APPLICATIONS

CONTACT US

Applications

Home > Applications

Dust collection filter bags

Power plant

power development is the key to the economic development for any country. A range of pollutants are generated from coal-fired plants. Coal fired power generation plants have for a number of decades been recognized as environmental concern. Without filter bags there would be large quantities of fly ash emitted to the atmosphere. Today power generation plant emission levels operate well below the Government's tight environmental laws. This is partly due to the performance of filter bags.

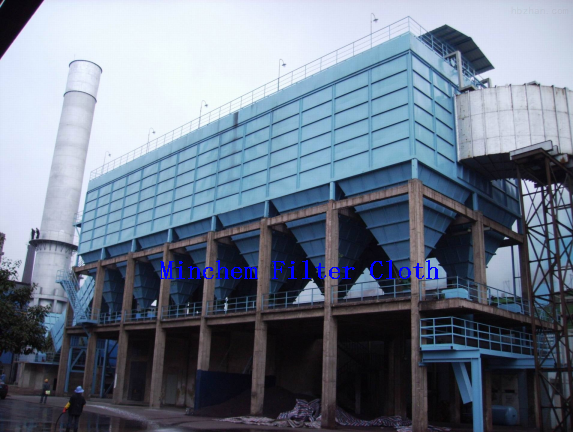

When coal is fired in the massive furnaces it leaves behind a very fine residue, called fly ash. The fly ash is drawn to and caught on hundreds of long open ended filter bags that are suspended in the bag house area of a power plant. The bag house operates at a temperature of between 120 to 140 degrees Celsius. Periodically the filter bags are shaken and the ash falls into hoppers where it is collected and taken away to be recycled.

Our company designs & manufactures an extensive range of filtration systems used in power generation for its liquid, gas, hydraulic & lube oil and air filtration. Numerous systems have been developed and applied for control of Particulates. Some control like specifically one type of pollutant; whereas others may integrate several control systems.

For Various applications of power plant generation our company provides the most comprehensive, cost-effective and reliable filter bag products.

The main product used for power plant is PPS filter bag. PPS filter bag can work under high temperatures. It has excellent dust removal effect and long service life. PPS fiber can keep intensity completely and bear chemistry inherently, keep good filtration performance among the abominable environment and reach ideal service life.